What's Under Your Solar Panels?

Do you know what's really under those roof-mounted solar PVs you just installed? You should. Not fully understanding the commercial roofing system underneath the solar array can have a negative impact on your customer, and leave you exposed to unwanted liability. Learning the fine points of a roofing system will help minimize your risk, and keep your customers happy.

The Composition of a Commercial Roofing System

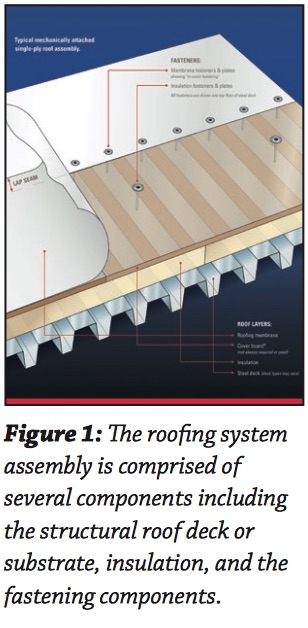

Commercial roofing systems are far more than just a waterproofing cover - although keeping water out of the building envelope is still its primary purpose. The system, usually referred to as an "assembly," is comprised of several components, including the structural roof deck or substrate, insulation, and the fastening components that hold it all in place. Smart building owners and solar installers know that the roof system under a solar array has to last as long as the solar system does, because once solar is installed, replacing the roofing system is time-consuming and expensive.

1. The Deck

The structural roof deck - also known as the "substrate"- can be made of several different materials including steel, gypsum, concrete, or wood. Before installing any solar products, it is important to know the composition of the deck, since that may affect the design, installation, and attachment method of a solar rack system.

2. Insulation

Rigid insulation is usually installed directly on the deck. The most popular type of insulation used in North America is polyisocyanurate (iso). Other insulation choices include extruded and expanded polystyrene, and mineral wool. In addition to these "base" materials, high density cover boards made of gypsum or iso are frequently used in commercial roofing. Generally speaking, high-density cover boards are better able to handle the foot traffic and compressive loading of a PV system, and are also beneficial when additional ballast is needed. Without a hard or dense cover board, the ballast may compress the insulation slightly, creating low spots on the roof where dirt, debris, water and ice can collect. Not only can such ponding water cause long-term problems; even ballasted racks can and do move around on the roof as the racking system and/or building and components expand and contract. Any dirt or debris trapped under the rack can consequently be ground into the roofing system, eventually leading to a difficult to detect, and hard to repair, leak.

3. Waterproofing Cover

The final layer consists of a waterproofing cover over the top, which is designed to keep water out of the building envelope. While there are several different types of commercial roofing materials available, the market favors single-ply materials, including white thermoplastics (PVC or TPO), and black rubber (EPDM). Asphaltic materials, called built-up roofing (BUR), and modified bitumen (mod bit) - characterized by redundant layers of roof felts - are also used in commercial roofing. Solar installers need to know what type of roof is installed in order to determine the best way to secure the solar panels without compromising the integrity of the roofing system.

Roof and Solar Attachment Options

1. Ballast

Today, most roof mounted solar rack systems are designed to be secured in place with ballast (usually, cement blocks or pavers). One reason ballast is used is due to a widely accepted perception that penetrating the roof is bad. Many solar installers also believe that by not penetrating the roof, they will not void the roofing warranty. This is not a good assumption; most commercial roofing warranties include an overburden clause stating, in effect, that anything added to the roof without notifying the roof manufacturer will void the roof warranty.

Over the past 20 years, the commercial roofing industry has moved away from using ballast on roofs, due to the dead load weight it adds to the structure, as well as the effect wind can have moving the ballast around and off the roof. Additionally, most of the newer commercial buildings aren't designed to accommodate the additional weight of ballast. As a result, the commercial roofing industry has adopted mechanical fastening methods for securing the roof, almost eliminating entirely the use of ballast.

2. Mechanical

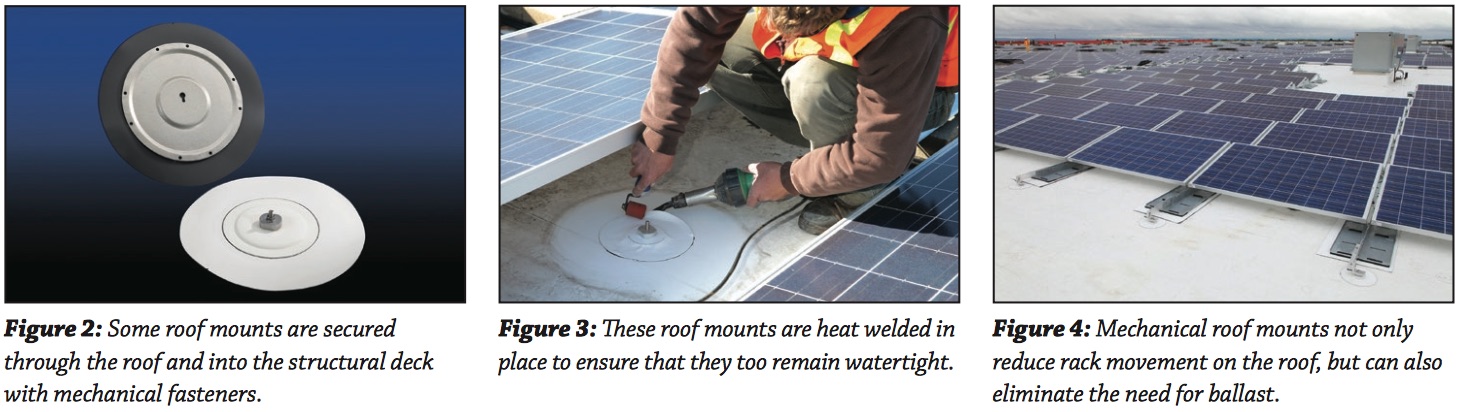

Roofs are mechanically attached using screws and "plates", or oversized washers, to attach the roofing membrane to the deck. With thermoplastic membranes, the seams are hot air welded to create a monolithic, watertight panel.

With the right type of roof mount, solar array systems can be secured to the roof in a similar manner; installers can avoid having to cut the roof open down to the structural deck, installing a support, and then rebuilding the roof and flashing the penetration.

Instead, such roof mounts are installed on top of the roofing system, but secured through the roof and into the structural deck with mechanical fasteners - the same fasteners that likely holds the roof system in place. The mount is then heat welded in place to ensure that they also remain watertight. The end result is a system that not only reduces rack movement on the roof, but can also eliminate the need for ballast.

3. Don't Forget the Warranty

Finally, be sure that installing a solar rack system will not void the roofing warranty. Building owners usually purchase a long-term warranty for the roofing systems. Roofing warranties have terms ranging from five to 30 years, so it's important that, prior to starting any work on the roof, solar installers confirm any limitations of the warranty.

It's also important to understand that most roofing warranties require that a contractor authorized to work on the roof, carefully observe the roof system manufacturer's specifications. So it's always advisable to read the existing warranty; contact the roof system OEM and work with them, through the building owner, to ensure that the roof remains covered under the warranty.

Roof Smarts Means Successful Solar Systems

Solar installers who take measures to understand the roof beneath their racks are more likely to provide their customers with a long-term, dependable, and efficient solar system.

Chris Mader is a codes/approvals support engineer for OMG Roofing Products. He's responsible for helping to evaluate new products, as well as developing and maintaining technical product specifications, maintaining code approvals and keeping abreast of technical changes and advancements in the commercial roofing industry. Chris is a member of the NRCA, SPRI and of RCI.

OMG Roofing | www.omgroofing.com

Volume: 2017 July/August

.gif?r=8417)

.jpg?r=6758)

.jpg?r=1266)