PV Asset Management

Implementing a solar plant dashboard for reduced O&M costs and increased profitability

Would the average consumer invest in the stock market without real-time insight into financial performance? Not a chance. We live in a world that craves information, preferably easily accessible and digestible information, especially when it pertains to a major financial decision.

Shouldn’t the same hold true for PV installations?

PV projects are increasingly seen as secure long-term investment opportunities. Like any financial asset, PV systems must be monitored and managed to realize their full potential.

With traditional string inverters, O&M providers have access to limited information. String level or system level monitoring can indicate underperformance of the array but little else. Skilled technicians have to perform inefficient onsite troubleshooting on inverters operating under load and on DC lines at nearly 1500V. They connect expensive equipment to the arrays in an effort to ‘sift through the tea leaves’ of complex IV trace curves to detect issues.

Fortunately, the standard in PV monitoring has been optimized. With MLPE (Module Level Power Electronics) devices, like power optimizers, O&M providers can remotely manage many of the issues. MLPE devices report module-level Voltage and Current at Max Power Point values over the World

Wide Web. This provides the O&M company high-resolution data on module-level performance to diagnose many issues, without the need to be onsite.

The most advanced PV monitoring and management solutions have the potential to take O&M from a manual, resource-intensive process to an automated, at-a-glance service. More than just a system overview, MLPE solutions deliver module-level insights and ensure a plant is performing to the best of its ability at all times. Intelligent, MLPE-supported cloud-based solutions also offer the ability for computers to do most of the work with automated reports and alerts:

- In-depth analytics and reporting on energy yield, system uptime and financial performance

- Automated, pinpointed alerts for immediate fault detection

- Remote diagnostics for smarter maintenance planning

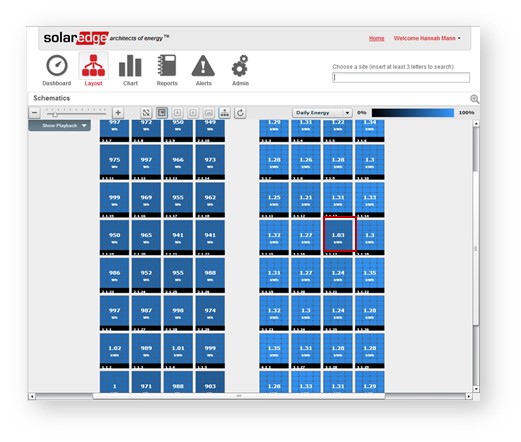

For example, figure 1 identifies module 17 in string 1 of inverter 3 as underperforming compared to its neighbors. Today’s monitoring systems are able to detect underperformance like this and may be programmed to send automated alerts to the service providers.

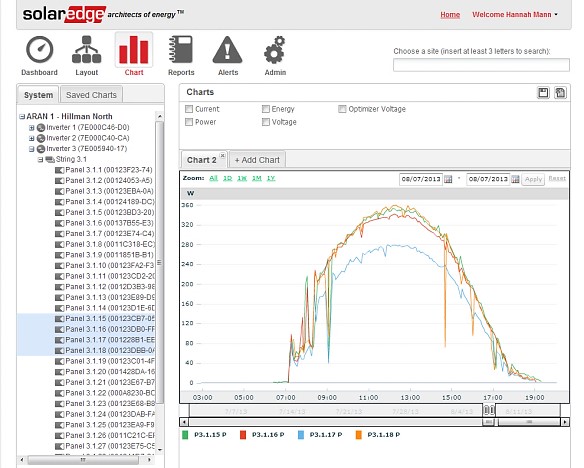

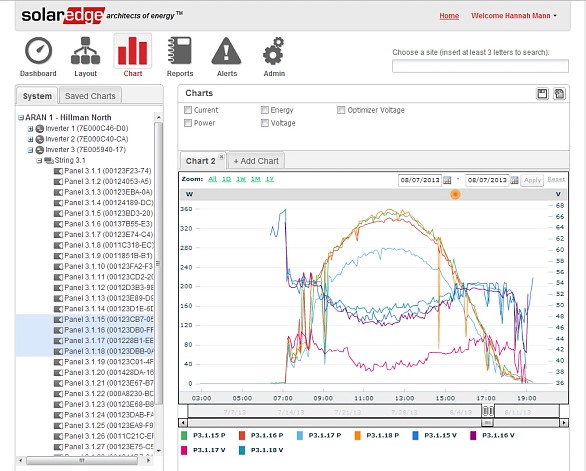

Once alerted, the technician, with just a couple clicks of the mouse, can gather more data on the power, voltage, and current output of the problem module (figures 2 and 3). By comparing this module with others in the same array which are performing properly, the O&M provider can make determinations as to the possible failure modes.

Once alerted, the technician, with just a couple clicks of the mouse, can gather more data on the power, voltage, and current output of the problem module (figures 2 and 3). By comparing this module with others in the same array which are performing properly, the O&M provider can make determinations as to the possible failure modes.

With such precise data at their fingertips, solar professionals and system owners can now easily and accurately identify performance challenges (in the above case, likely a failed diode) and rapidly resolve problems. The result is a win-win; technicians can more efficiently manage portfolios from a central location and identify problems before setting foot at the project site. This gives O&M providers a “Know Before You Go” advantage. They can load the truck with the correct parts to fix the issue the first time. Less on-site maintenance calls (also known as “truck rolls”) for the professional means a lower support cost and the ability to support more sites more efficiently. Plus, system owners win with less system downtime eating into their profits.

Since the MLPE devices are persistently connected to the array, they are able to store data in the cloud for the system’s entire lifetime. By analyzing historical project data in a monitoring portal (figure 4), module-level monitoring and management tools can also help stakeholders evaluate and predict system performance, and financial returns, for a given period. This comparative year-over-year snapshot enables smarter financial planning for the system owner.

Since the MLPE devices are persistently connected to the array, they are able to store data in the cloud for the system’s entire lifetime. By analyzing historical project data in a monitoring portal (figure 4), module-level monitoring and management tools can also help stakeholders evaluate and predict system performance, and financial returns, for a given period. This comparative year-over-year snapshot enables smarter financial planning for the system owner.

As the global solar market continues to grow at a record pace, project owners and service professionals are recognizing the need to minimize risk and make better-informed decisions on how to support their PV assets for 25 years or more. With the breadth of capabilities offered, it’s no wonder that MLPE devices connected to cloud-based monitoring portals are taking root as a de-facto, dashboard-like solution for efficient problem solving, and an indispensable component of lucrative long-term PV investments.

Peter Mathews leads the North America team as general manager for SolarEdge in the Americas and is responsible for all business activities. He is a veteran of more than 25 years in the global semiconductor and solar industries in senior sales, marketing, and business development roles. He has led various companies through the start-up, IPO, and growth phases including Enecsys, Solyndra, and FormFactor.

SolarEdge | www.solaredge.com

Volume: 2016 March/April

.gif?r=7530)

.jpg?r=8453)

.jpg?r=9263)