Maximizing Energy Harvest: Through PV inverter innovations

The concept of inverter innovations for solar power encompasses advances in functionality, as well as novel approaches to inverter implementation. Both elements play an important role in maximizing the potential of this critical photovoltaic (PV) system component, with the goals of increasing energy harvest and long-term system returns on investment (ROI).

The concept of inverter innovations for solar power encompasses advances in functionality, as well as novel approaches to inverter implementation. Both elements play an important role in maximizing the potential of this critical photovoltaic (PV) system component, with the goals of increasing energy harvest and long-term system returns on investment (ROI).

Although maximizing energy harvest is a top priority for any renewable energy project, the particular inverter-related strategy for achieving this goal is typically determined by a specific industry condition or technical issue. Conditions and issues, including the pervasive effort to reduce upfront costs, compliance with utility regulations, and loss of production due to DC losses and system downtime, are the main catalysts for the innovations described herein.

Higher DC-to-AC Ratios: Maximizing returns

Traditionally, DC-to-AC ratios have varied between 1.2 and 1.3. However, site designers are increasingly pushing this number upward into the 1.5 and 1.75 range, and inverter manufacturers have responded with concomitant hardware and software capabilities. Of course, the desire for higher power densities and increased energy harvest is the primary motivator for the upward trend. However, the main catalyst for this particular strategy is the PV industry’s historical focus on reducing balance-of-system (BoS) costs.

Variable project costs, which increase with system size (and usually include components such as modules, racking, combiners, and trackers), have declined significantly, enabling larger project sizes with minimal increase in upfront investments. This has prompted developers and designers to utilize fixed costs, such as inverters, to their maximum possible potential energy harvest, resulting in a demand for increased inverter AC-to-DC ratios.

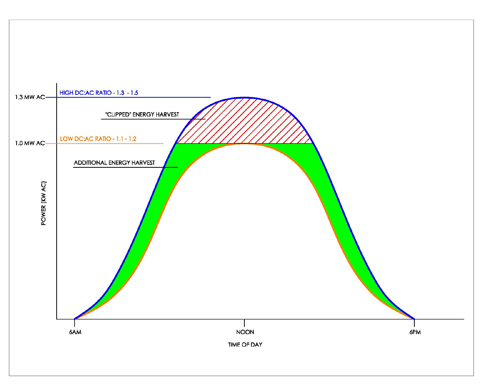

One effect of this trend is the phenomenon of production “clipping” in high-irradiance months (see Figure 1). Generally, during the months of the most intense sunlight, inverters do impose specific production limits in projects with high DC-to-AC ratios. However, the energy gain throughout the year that results from the high ratio and power density compensates this loss.

Power Factor Capability: Meeting utility requirements

Over the past four years, inverter technology has advanced in specific ways to enable functionality mandated by utilities and to eliminate related production losses. For example, the California Public Utility Commission’s “Rule 21” requires inverters connected to the grid go offline and stop producing power during abnormal grid conditions, such as voltage and frequency highs or lows. These interruptions in power production result in loss of energy harvest.

With the recent years’ growing investments in solar energy, a larger number of inverters are now connected to the grid. If these inverters, in compliance with Rule 21, all shut down simultaneously, it could seriously destabilize the grid and jeopardize reliable power delivery to energy consumers. To help mitigate grid instability, a recently proposed revision to Rule 21 would require inverter manufactures to provide grid support, such as low/high voltage and frequency ride-through, along with reactive power support.

In anticipation of this revision, an in response to local grid studies, many utilities are already requiring distributed energy resources to provide grid support. Currently, Rule 21 only applies in California. But, with the increase in distributed generation, it’s slowly being adopted by utilities across the nation—and, therefore, affects all inverters nationwide.

Inverter functionality has advanced to keep pace with these requirements and to maintain energy yield. Settings, for instance, can now be modified to ride-through voltage or frequency anomalies, preventing any loss of production related to grid instability.

The ability to support grid stability in cases of a line voltage or frequency excursion is not a new inverter function. However, the ability to do so without sacrificing power production is a more recent concept. Reactive power capability increases or decreases line voltage to compensate for low or high voltage conditions on the grid, respectively. Previous inverter technology may have had this capability, but it was at the expense of real power, reducing the annual yield.

Today, savvy developers select inverters that have broad reactive power capability to meet utility grid support requirements without sacrificing real power production, thereby maintaining the solar plant’s annual yield.

Bi-polar Technology: Minimizing DC losses

Certain advances in PV inverter technology have enabled innovative system design strategies that increase production by reducing DC conductor losses. Mono-polar architectures utilize string combiners and re-combiners to collect the conductors, increasing the conductor size for ampacity and voltage drop before running back to the inverter.

Limiting voltage drop to roughly 1.5% to 2.0% can minimize energy losses, but the increase in conductor size to compensate for this drop in voltage can significantly increase upfront costs in larger arrays, quickly eroding the benefits of higher energy production. Additionally, conductor length is limited by energy loss resulting from long runs. The inability to use long conductor runs can, then, limit the overall size of the generating array block, resulting in lower plant yield.

Bi-polar technology can lower overall circuit length by roughly 50% by enabling the use of either a remote PV tie or combiner PV tie to connect two separate arrays together before running back to the inverter. This topology, being less susceptible to energy loss resulting from excessive DC run length, allows the size of the generating array block to increase, increasing the overall plant yield.

Distributed & Central Plant Architectures: Reducing downtime

Innovations in inverter-related project design, as well as advances in inverter functionality, can reduce losses due to system downtime. Plant failures are often caused by a fault in the array, such as a ground-fault or high-resistance connection. These events are often specific to only a few circuits, but the associated inverter must be taken out of service so the fault can be repaired.

The benefit of a distributed architecture in this situation, which uses multiple string inverters, is that only the inverter associated with the fault needs to be taken out of service during repair. The loss of energy harvest is limited to one inverter, while the remaining ones continue to produce power. Furthermore, the offline string inverter’s power is much lower than that of a central inverter (ex. 20 kW vs. 500 kW)—resulting in lower energy loss when a single string inverter is taken out of service, compared to a central inverter.

In comparison to a distributed architecture, shutdown to repair a fault in an array with a central architecture typically affects a much larger portion of a plant, resulting in significantly higher energy losses. A central inverter with built-in DC monitoring capabilities has the ability to isolate and shutdown specific DC circuits. The inverter can, then, be brought back online while the isolated circuit is investigated, mitigating loss of energy harvest during system faults and delivering the same advantages related to plant downtime offered by string inverters.

Summary

Maximizing energy production through PV inverter innovation is a multi-faceted subject, with much room for invention and a variety of drivers. As industry conditions evolve, so will these drivers and the resulting strategies, with plenty of opportunity for developers, designers, and equipment suppliers to pioneer new methods and functions to maintain the continued upward trend of solar energy production and revenue.

Alex Griffiths is a field applications’ engineer for Advanced Energy’s Solar Inverter division.

Advanced Energy, Inc.

www.advanced-energy.com

Author: Alex Griffiths

Volume: November/December 2014

.jpg?r=2510)

.jpg?r=3105)

.gif?r=8690)